Let’s for over the modern top building and construction innovation we have today. No one of those would be reachable without advanced laser levelers solutions.

Canada: 18-story wooden dormitory

At the time of its settlement in September last year, the Canadian Columbia University dormitory was the tallest wooden building in the world. It was built from a cross-glued beam, which surpasses steel in strength and is very resistant to fire.

The 53-meter-high building, dubbed Brock Commons, was designed and built by Acton Ostry, a Canadian architecture firm. As its representatives emphasize, all the wood that went into the production of timber was extracted in the forests of British Columbia. The construction process, with the exception of interior decoration, met a record 70 days. The hostel is designed for 400 students who currently live in it.

In fairness, it should be noted that the cross-glued beam CLT (cross-laminated timber) is not a novelty in the building materials market: it appeared on the market in the 90s of the last century. Numerous layers of this material are glued in such a way that the fibers of the previous layer are always perpendicular to the fibers of the next. This technology gives the material high strength, while its production is virtually waste-free. Innovation is the construction of high-rise buildings around the world from CLT and other modern wood processing products – a special word plyscraper even appeared to indicate them, by analogy with the well-known skyscraper.

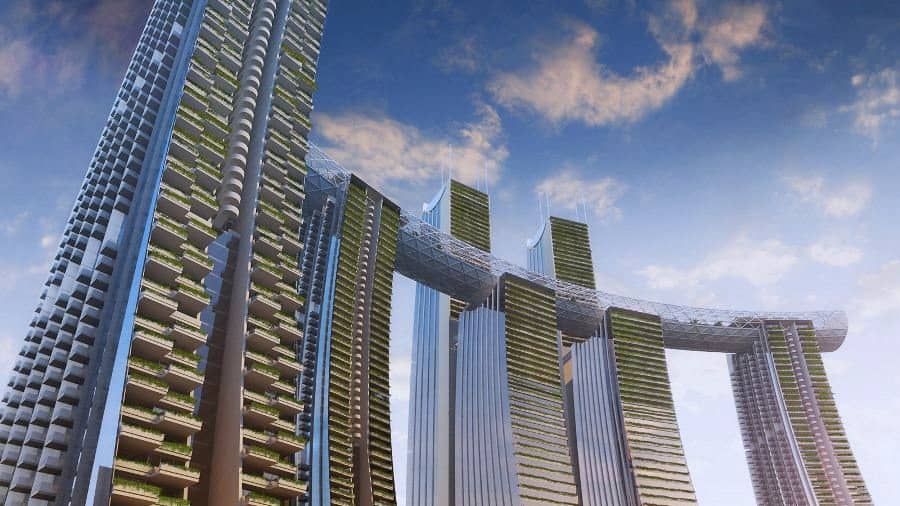

China: Horizontal Skyscraper Conservatory

China has repeatedly struck the whole world with the scale of its construction projects, whether it be the Great Wall or the world’s longest suspension bridge. This time in the Chinese city of Chongqing, they took up the construction of a horizontal Conservatory skyscraper, which will rely on the roofs of four high-rises of 250 meters in height. The author of the project was the architect Moshe Safdi, the contractor was CapitaLand. The complex of buildings will include two more high-rise buildings, the construction of which is being carried out simultaneously with the construction of a horizontal skyscraper. All seven buildings will be connected to each other by elevated passages and make up a single architectural ensemble.

Inside the Conservatory there will be apartments, hotels, offices, a shopping center, and a spacious relaxation area with a swimming pool, gardens, and observation decks. The weight of a slightly curved horizontal tower is 12 thousand tons. Its construction will require 3200 glass and 4800 aluminum panels. The design consists of nine segments, four of which will be assembled on-site, one on each of the skyscrapers. Three intermediate segments are welded on the ground and lifted to the installation site by hydraulic jacks. And finally, the two extreme segments will be assembled from the short sections last. They are planning to complete the installation of the structure this year.

The horizontal Conservatory skyscraper, like the entire Raffles City Chongqing building complex, is being built in accordance with the LEED Gold green standard. It provides measures to reduce the absorbed heat and an effective irrigation system, which will reduce the cost of air conditioning the building. The issues of reuse of construction waste and their disposal are also thoroughly worked out.

As the engineering firm Arup, responsible for the safety of the complex of buildings, assures, the seismic and wind resistance of the buildings will be at the highest level and for this, the most advanced laser scraper needs to be used.

To complete the construction and solemnly open the Raffles City Chongqing, which also includes the horizontal Conservatory skyscraper, builders expect next year.

Netherlands: Sea Salt Building Blocks

Building from salt, which in the proverbs and sayings of different nations is a synonym for futile efforts, the Dutch architect Eric Jobs managed to turn it into reality by developing an environmentally friendly technology for the production of blocks based on seawater.

Using solar energy, salt is extracted from the ocean and then mixed with starch, which is obtained from seaweed. The output is blocks similar to bricks, which have high compressive strength. Buildings made of such blocks are covered with epoxy resin-based material, after which no moisture can damage them. Blocks of salt are quite suitable for creating flexible arched structures.

For arid countries, Eric Jobs emphasizes, this construction technology is optimal. The first small city, completely built from salt blocks, will be erected in Qatar.